Home made battery capacity tester for primary and rechargeable cells

I have found the life of fully charged NiMh rechargeable batteries is incredibly variable within one batch. I suspected my fairly new rechargeable batteries are either self-discharging at an alarming rate, or the capacity varies.I decided to design a tester which almost anyone can make, at minimal cost, mainly from old junk. The tester must produce repeatable results, and compare batteries to make matching sets. It should also give a good approximation of capacity in mAh.

When replacing a watch battery the other day, it hit me.. Why not make a battery tester out of an old quartz analogue watch! It has a non-volatile memory (the clock face) and reacts to the battery going flat (stops). I had a couple hanging around in a drawer, one being a watch I bought last year for 3.99 at a local market, which quickly deteriorated. The tester uses a shunt resistor to drain the battery. The watch times how long the battery takes to go flat. As NiMh batteries terminal voltage drops very quickly as they get to the end point, the actual voltage at which the watch stops isn't too critical. Mine stops at exactly 1 volt, which is fine.

I designed the circuit to draw 250mA from the battery. This rate is within the abilities of good NiMh (Nickel Metal Hydride) and NiCd (Nickel-Cadmium) cells, and represents a very high drain device for AAA and moderate drain for D size. The discharge rate is too high for meaningful results with Zinc-Chloride below C size, and Zinc-carbon below D size.

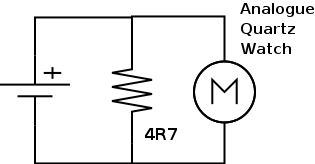

Circuit Diagram

Parts required

- Old analogue watch. Must use single 1.5v cell

- Suitable battery holders (I used Maplin Part Nos YR59P AA size 29p and BK46A D size 49p

- 4.7 ohm resistor (also known as 4R7) Maplin code M4R7 7p

- Suitable substrate. Piece of wood, hardboard etc

- Thin hookup wire for inside of watch

Tools required

- Hand drill or power drill

- 2-4mm drill bit

- Soldering iron with fine point

- Flux core solder 18-22swg

- Sticky pads or hot melt glue gun

Method

- Open watch back. Remove battery

- Solder a piece of hookup wire to each side of the battery compartment.

- Drill hole in back of watch

- Thread hookup wire through hole in watch back. Mark each wire for polarity. The negative is the disc at the bottom of the battery. The mechanism is usually positive. Replace watch back

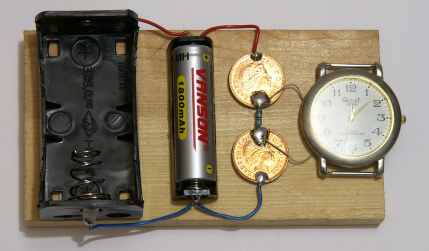

- Shorten resistor wires then solder each leg to one coin. Solder may only take to copper coins. The coins act as heat sinks and help mount the resistor

- Remove retaining flaps from battery holders with flush cutters or side cutters. These are designed to hold the battery firmly in the holder. As we will not be moving the holder around, the batteries will be held firmly enough by springs and the flaps will get in the way when swapping cells.

- Mount watch onto board, making sure winder protrudes over side of back board. You will need good access to winder to return watch to 0:00 each time you change battery. Mount battery holders to board

- Solder your chosen battery holders in parallel. (The D size holder accommodates D, C or AA and the AA size holder accommodates AA or AAA size cells)

- Solder watch wires to resistor/ coins observing polarity. Solder wires from battery holders to resistor/coins

- Once coins have cooled, mount to back board

Results

Out of a batch of 10 identical NiMh 750mAh batteries, I found the batteries to last the following times.- 0:08

- 0:12

- 0:30

- 0:37

- 1:00

- 1:15

- 1:25

- 1:45

- 2:04

- 2:32

The discharge rate is around 250ma so 8 minutes corresponds to 33mAh and 2:32 corresponds to 633mAh. Your equipment will only function for as long as the weaker battery holds out.

MiMh batteries are said to need 5 charge/discharge cycles for them to reach final capacity. The very poor 8 minute battery improved to 35 minutes then to 1 hour 15 minutes before returning to 56 minutes on it's fourth charge/discharge cycle.

Notes

This unit also helps recondition batteries. Nickel cadmium batteries benefit from complete discharge/recharge cycles to help remove memory effect. NiMh cells benefit from complete charge/discharge cycles when new to bring capacity up to scratch. The complete discharge cycle doesn't work in most equipment; the equipment will only run until the weakest cell fails. The other cells will not get their full discharge cycle. This unit will continue discharging until the cell is really dead, without any chance of accidental reverse-charging.The following table assumes an average battery terminal voltage of 1.175v. In practice, it may be slightly higher than that, but will usually be within 6%.

| Time | mAh |

| 15 | 62.5 |

| 30 | 125 |

| 1:00 | 250 |

| 1:30 | 375 |

| 2:00 | 500 |

| 2:30 | 625 |

| 3:00 | 750 |

| 3:30 | 875 |

| 4:00 | 1000 |

Build pictures